A liquefied gas carrier lost propulsion while departing the Port of Brisbane after an electrical blackout caused by generators that were not set for automatic load sharing.

Operational Conditions Before Departure

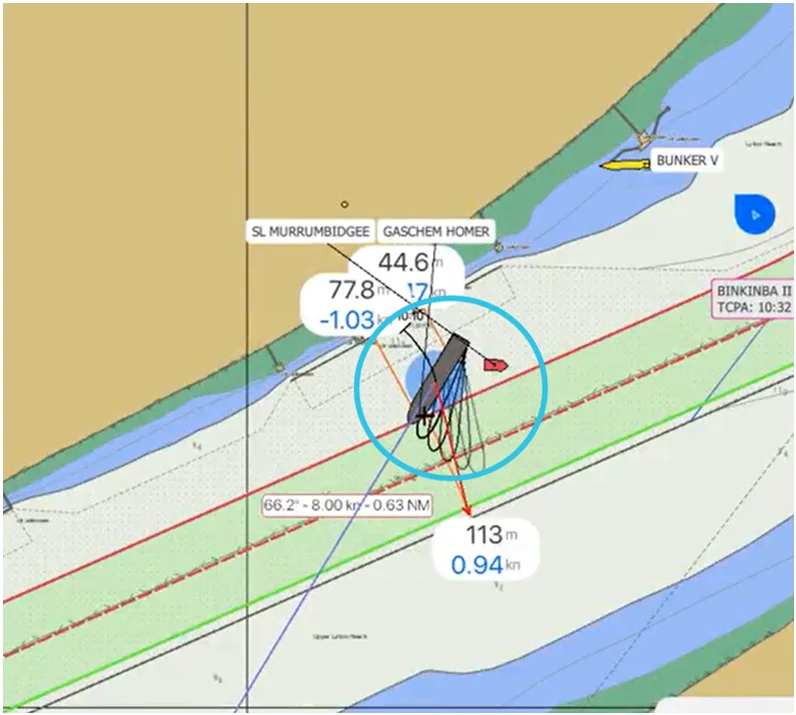

On 15 March 2025, the 100-metre gas carrier Gaschem Homer was departing from the BP Products berth in the Port of Brisbane under pilotage. The vessel had completed cargo discharge operations at 4:24 a.m. after arriving on 14 March 2025. Recent heavy rainfall had resulted in debris and stronger ebb flows along the Brisbane River, leading to temporary movement restrictions and the allocation of a tug for departure.

During standard preparations, the crew started all three diesel generators and conducted equipment checks, including tests of the bow thruster and main engine. While two generators were synchronised for automatic operation earlier, they were returned to manual mode and left in that state.

Electrical Blackout During Manoeuvring

At 11:04 a.m., while the ship was being turned towards the port entrance, the only generator available for load sharing overloaded when the bow thruster was operated at full thrust. This resulted in a complete loss of electrical supply, propulsion and steering.

The blackout lasted about two minutes. During this period, the attending tug kept the ship centred in the channel while the crew restarted generators and restored power. No injuries or damage were reported.

Findings from the ATSB Investigation

The ATSB determined that the generator configuration prevented the power management system from distributing electrical load across multiple units. Although all generators were running, two were in manual mode, meaning they could not share load. The blackout occurred when the single available generator tripped due to overload.

The ship’s safety management system relied on generic procedures that did not reflect the specifics of the ship’s electrical systems. The pre-departure checklist included only a broad reference to generator readiness and did not require confirmation of generator mode status. With the crew focused on monitoring debris risks to cooling systems, the incorrect configuration was not detected.

Safety Actions Undertaken

Hartmann Gas Carriers conducted a risk assessment of power management failure modes across its fleet. Additional safety controls were introduced, including guidelines for blackout prevention and procedures to ensure generators were configured for automatic load sharing during manoeuvring.

Checklists for departure and arrival were revised to include generator mode verification. A power demand matrix was developed to specify generator requirements under different operational conditions. Targeted training for watchkeeping engineers and improved communication processes between the bridge and engine room were also implemented.

Implications for Vessel Operations in the Port of Brisbane

The incident demonstrated how an incorrectly configured power system can lead to propulsion loss in a confined and high-risk environment such as the Brisbane River. The updated procedures, verification steps and training aim to reduce the likelihood of similar events during future operations.

Published 20-Nov-2025